” I have noticed uneven expansion in my target rifle brass. Rifle shoots well but has always been a bit hard to eject. The pics show that the shells are expanding to one side but not the other. (These are once fired Winchester brass left side and right side of the same shell). Could it be that when re-barrelled and the chamber reamed that it could have not been centred correctly? ”

Peter Maher LERAA Shooter/Secretary/Treasurer

Ok, next thing I will put up for discussion is the reason found for the cases to expand unevenly by a bunch of us on an international collectors forum before gunboards existed…

We all accept that the “generous” size of the milspec chamber is solely for the reason of being able to chamber and fire rounds in the worst of fighting conditions. WW1 trench warfare.

Being a rimmed cartridge that headspaces on the rim, meant that it didn’t matter what shape or size the chamber was in front of that rim, as long as the projectile was directed toward the lead and the case did not fail, it was perfectly suited to the job.

Enter the era of milsurp shooting, then the shortages of milsurp ammo leading to the need to handload. SAAMI made their commercial .303 cases smaller than the military spec, meaning there is space around the case in the chamber.

The bolt closes, the extractor claw is drawn away from the case. There is, in a milspec rifle a minimum of .064″ between the face of the bolt and the rear of the barrel that the cartridge rim contacts. Milspec case rims max thickness is .063″ meaning that at it’s tightest, there is .001″ “head gap” between a chambered case and the bolt face. Run this out a few thou for correct headspace and then a few thou more for undersize SAAMI rims and it’s not unheard of for there to be .014 or more head gap.

Lets agree that the cartridge is loose with the bolt locked and able to flop around.

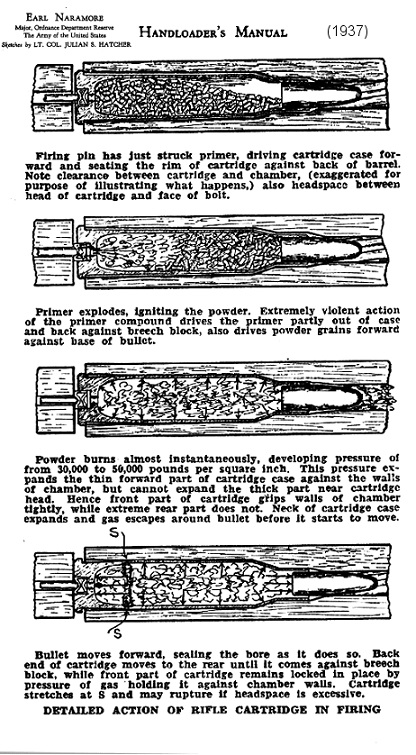

When the trigger is pulled, the striker comes forward and pushes the case in until it contacts the rear of the barrel. It then can indent the primer. At this point, the case flopping around the chamber is sitting in the bottom of the chamber.

Pressure from igniting the powder expands the case walls out to slam into the chamber walls. This SHOULD be happening according to physics, equally and opposite in all directions, BUT… the rear of the case is currently nailed in place with the tip of the striker, so the back of the case cannot lift off the floor of the chamber, only the top can expand out to the chamber.

While this is happening, quite often the primer backs out under pressure to contact the bolt face, then the base of the case expand back to the bolt face too.

What you end up with is the case all the way into the chamber and the walls expanding out and gripping the chamber. The base of the case then moves rearward until the bolt face stops it.

The majority of case wall expansion is to the top. The case is locked in the chamber, then the part where the walls meet the web is where the case stretches rearward. (this is what creates the weak point where case head separation occurs.)

If you look at your primers under a magnifying glass, you might even see that the indent is not concentric, and in fact it might even have a raised lip on one side.

If the case is at the bottom, the primer strike will be above center. If the case head has managed to move up at all (case expanding lifting it against the tip of the striker) it will have a raised lip toward the bottom- which will be toward the middle. Below shows the case centred in the chamber, but if there were a gap at the top, you can understand that the rear of the case is nailed in place by the striker, making expansion happen to wherever the gap is. Either at the top, or if the claw is contacting the case, the gap will be to the right side

My rifle seams to have the expansion happening more on one side, it is more than likely the claw creating the problem. My other smle rifles do have some expansion but it is more even around the whole case.

I’m going to try to work through the points concerning the above non-concentric fired case drama.

Part 1.

I will start with a fact, that may be something that the shooter needs to look at…

When the bolt handle is locked down, the extractor claw rides onto the tapered part of the recess in the rear of the barrel, to the right of the chamber. This releases the case from any effect from the spring tension of the claw.

This absolves the claw from being the culprit!

If the claw is still in contact with the case with the bolt closed, then it’s likely either the claw needs replacing (worn on the front edge or the screw hole) or a replacement barrel has not been set up right.

Below are two pictures, the first shows the rifle with the bolt almost down, just about to start the camming action moving the bolt head forward that last little bit to lock. (this camming action is to create primary extraction when lifting the bolt handle after firing)

Look at the position of the bolt handle and the reading on the dial indicator.

The second pic below is with the bolt handle closed right down. Note the position of the handle and note the reading on the dial indicator.

All reply pictures are supplied by Brad Hedges

Non concentric lead into lands?

I had this discussion with a bloke many years ago, an “x-spurt” who said the British somehow managed to machine the chambers crooked! Mind you, his excuse for the out of round fired cases was that the Indians (RFI) machined them out of round because of the monsoonal rains running down the barrels, so the chamber shape was to allow the water to drain off around a chambered cartridge! I still have a copy of that looney toons post!

How can I prevent or rectify uneven expansion of a fired .303 case?

A couple of decades ago, faced with nil available surplus 303 ammo and only commercial cases that failed after two or three firings for reloading, someone came up with a brilliant idea.

Why not make the case fit the chamber like a rimless case and headspace from the bolt face to the shoulder.

It is easy!

What was needed was a way to stop the cartridge being pushed forward away from the bolt face on firing, so that it did not have to stretch the very short area between the web and chamber grip to get back to the bolt face. This would fire form the case to a size that fitted between the bolt face and the shoulder with zero (or very little) head gap and no stretching at the rear.

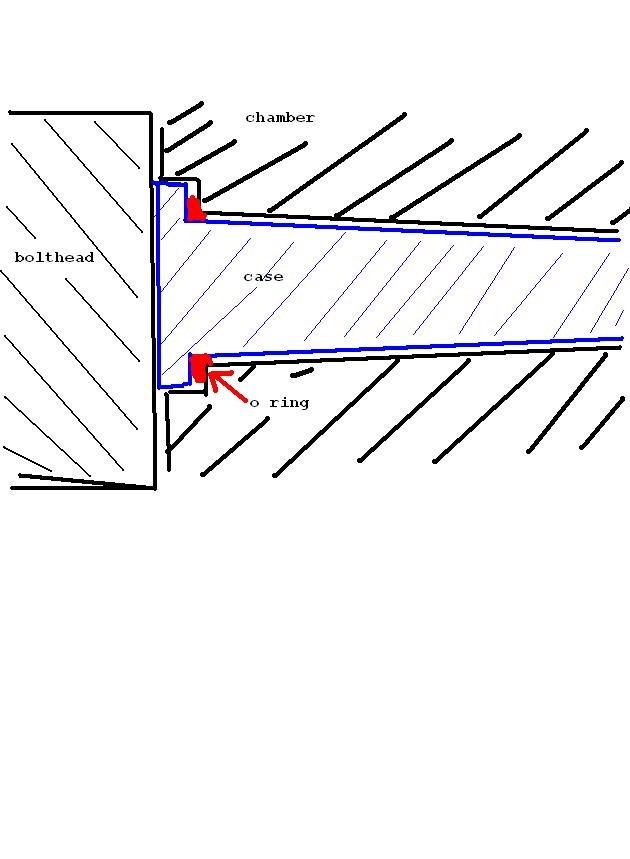

We used either a tiny O-ring or even tiny rubber bands slid onto the taper of the case up to the rim. When chambered, the O-ring would extrude into the gap between the front of the rim and the rear face of the barrel, holding the base of the case against the bolt face. If a fine enough or soft enough O-ring was used it would also fill a little of the gap around the case into the start of the chamber, effectively centering them.

When you chamber a round, it will be a little tight to lock the bolt down- (if too tight, try a smaller section O-ring). Once closed, firing will not open up a gap between the bolt face and the case because it is held back tight against it. The case walls will expand into the chamber, concentric if your choice of O-ring does it, and extrude forward to the shoulder. No rearward stretch, no thinning of the case wall at the web.

As it usually does, once the pressure drops your brass should spring back a tiny bit. Now, all you need to do is neck size unless your fireformed cases get a little tight to chamber, which is when you use a full length die backed right off and adjusted so it just bumps the shoulder back enough to chamber again.

What you will have done is removed the stretching at the base, fireformed the brass to headspace to the shoulder, and all but removed the need for full length resizing. After the initial firing, there is no working the brass.

Here is a kindergarten sketch of the O-ring in place. They only need to be used once per case and can be reused as long as they are not damaged.

If you have cases that are already bulged to one side, you can full length resize them and turn them 180 degrees in the die and press them again, should near bring it back to concentric.

Here’s the sketch.