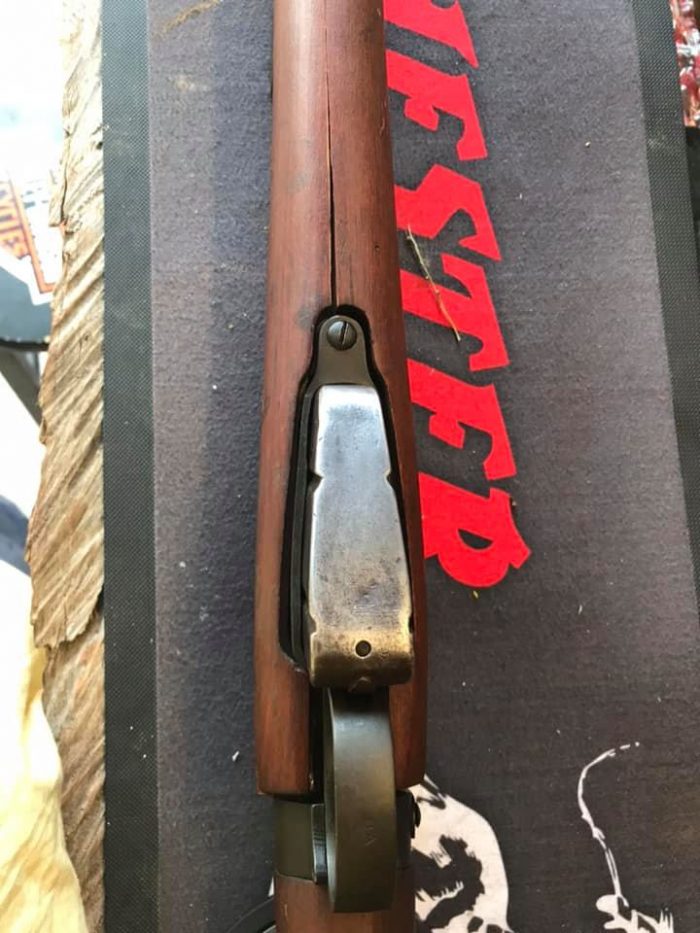

Thanks to Brad Hedges here is instruction to causation and repair of cracks in fore-end woodwork.

Cause: The crack was caused by the draws at the rear of the fore-end compressing or failing, allowing the fore-end to move forwards and backwards under recoil. Once the draws are stuffed, the next thing to absorb recoil is the front trigger-guard bush. Tightening the main screw does not grip the fore-end to the receiver, rather the bush is there to stop the screw and trigger-guard from crushing the fore-end and messing up the trigger to sear contact, resulting in losing the second pressure on the two stage trigger.

Once the fore-end moves around, the main screw bush acts like a wedge and breaks the fore-end.

Repair: You can open the crack up enough to get the glue of your choice in there. Clamp the crack closed. Drill through from one side to the other and put a length of the threadwire in the drill, slowly and steadily spin it in. This wire threads into both sides, so it won’t pull them together, but will hold them into the position you have clamped. If you screw the rod in just short of the other side you will have only one side to trim once all is set.

All of this work is for nothing if you don’t fix the draws as well.

The main screw bush needs to be floating and able to be adjusted if needed. It is supposed to be .2mm shorter than the wood so it holds firm, but does not crush.

“Wonky” draws are a problem, but the biggest reason No. 1 for-ends get mangled like that is “enthusiasts” trying to wind out the stock bolt before removing the fore-end. The square end of a LE / SMLE stock bolt was meant to be “constrained” by the square hole in that tie-plate.

The advent / discovery of the spring washer solved the problem in the No. 4 / 5 series.

If your fore-end is split like this, and has been for a while, one of the issues will be ensuring the cracks are clear of oil and detritus before attempting to glue it all back together. One way to get rid of a lot of the oil is to wash it out with something like “Carby cleaner” available from your local “auto supplies” shop. This is also an “outside job.

As for glues: traditional “slow” Araldite works. Better still is the “aviation-grade” wood glue used by folks who build their own aeroplanes. If it will hold the wings on, it will hold a split fore-end.

If you are holding things together while the glue sets, use long, narrow strips of inner-tube rubber. You don’t have to wind it too tightly as each layer will add compression to the one before. Experiment on a “practice” piece, first.

And good luck finding a good stash of that threaded brass wire.

Cheers,

Bruce

My contribution is that when you glue the wood back together that you leave the key in the back and also glue this into the repaired section.

Cheers

Steve

I am with you Steve I also drill and pin and glue on the inside in the back of the forend I get a cut off blade on a 4” grinder and cut a slot in the wood and lay steel pins in with acra glas gel this after I clean the wood work up with oven cleaner

David